Our pipe cutting and end preparation capabilities for commercial and mechanical contractors vary by location but can include:

|

|

|

|

|

|

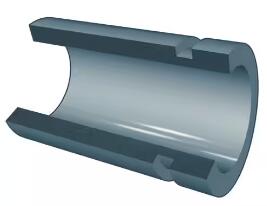

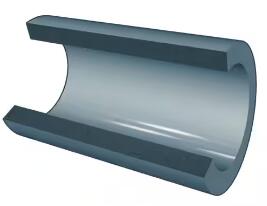

Cut grooving Carbon steel pipe down to ¾” |

|

Roll grooving standard or old style Carbon steel pipe from ¾” up to 36” Stainless steel schedule 10 pipe from 2” up to 12” Stainless steel schedule 40 pipe from 2” up to 24” |

|

Roll grooving cut to Victaulic AGS specifications Carbon steel from 14” up to 36” |

|

|

|

|

|

|

|

|

|

|

|

|

Threading Carbon steel from ½” up to 12” Stainless steel from ½” up to 4” |

|

Pipe cut to length - Square cut Carbon steel from ⅛” up to 36” Stainless steel from ⅛” up to 16” |

|

Pipe cut to length - Bevel cut Carbon steel from 2” up to 36” |